© 2020 All rights reserved

Curious about our company and what we’re up to? Stay updated with our blog.

02/02/2021

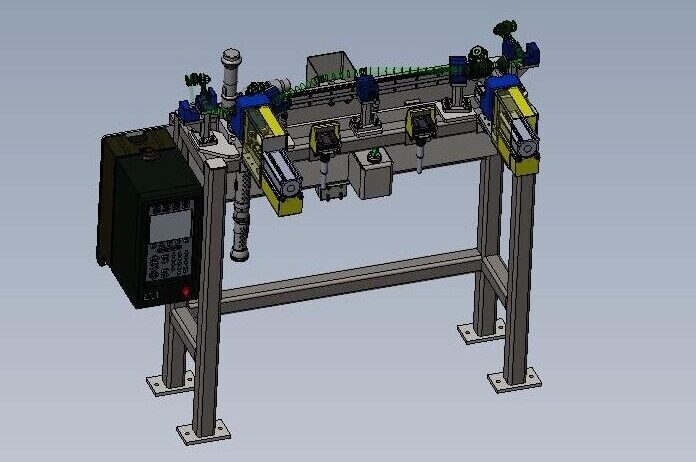

Custom designed equipment can be viewed as a risk, but the bottom line is that having equipment manufactured specifically for your needs will make a great return on your investment. Continue reading to learn how!

Assembly lines are successful when all parts are moving smoothly. Equipment that is custom designed allows you to create a product that addresses the exact concern. Achieving peak efficiency comes from assessing the problem, and designing a solution that will work flawlessly, every time.

Many business owners and managers shy away from custom equipment due to the potential high initial costs. When looking at the bigger picture, custom equipment can increase production productivity and lower overhead costs for labour and material – returning on your investment!

Custom ergonomic features greatly reduce worker strain and fatigue allowing for, once again, increased productivity. The health and safety of your workers is not only your top priority, but a priority to the company manufacturing your custom equipment. During the process of manufacturing equipment, tests and safety checks are frequently preformed.

When you are using a custom design and manufacturing company, the quality of the final piece(s) of equipment improves tremendously. Working with experienced equipment engineers, machinists and pneumatic specialists ensues that you will receive the best possible outcome every time.

Here at Stak Industries + TH Solutions, we pride ourselves on the quality of our equipment and offer extensive training and install support to maximize efficiency in your assembly lines. Extensive manuals, training and access to spare parts protect your investment and extend the lifecycle of your equipment. (another benefit!)

© 2020 All rights reserved